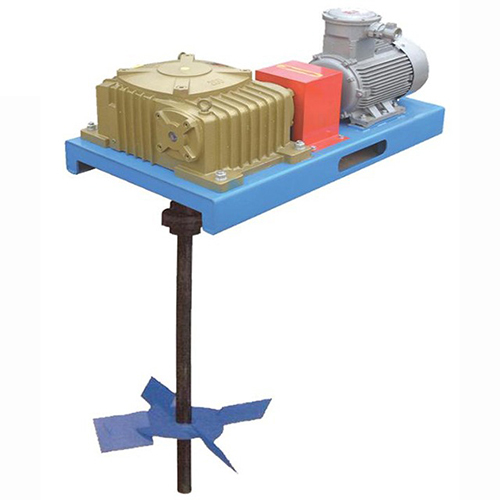

Industrial Agitator System

Price 100000.0 INR/ Unit

MOQ : 1 Piece

Industrial Agitator System Specification

- Phase

- Single/Three phase

- General Use

- Industrial

- Material

- Stainless Steel Alloy

- Automatic

- Yes

- Surface Treatment

- Polishing

- Voltage

- 220-440 Volt (v)

- Feature

- High Performance

Industrial Agitator System Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 20 Days

- Main Domestic Market

- All India

About Industrial Agitator System

Unlock gilt-edged efficiency with our premier Industrial Agitator System, perfect for general industrial applications. Utilise this high-performance equipment, designed for automatic operation and constructed from robust mild steel. Personalise your plant operations with a system compatible with single or three phase, working efficiently at 220-440 Volt (v). The deep surface polishing ensures longevity and reliability for distributors, manufacturers, traders, and suppliers across India. In demand for its durability and adaptability, this agitator system offers unmatched mixing consistency for your process, making it an offer you cannot miss.

Industrial Agitator System: Features & Applications

The industrial agitator system delivers high-performance mixing, automatic functionality, and lasting durability thanks to its polished mild steel construction. Engineered for both single and three-phase operation, it adapts seamlessly to the varied needs of industrial plants. Widely utilised across chemical, pharmaceutical, and food industries, its application area covers blending, homogenisation, and suspension tasksmaking it an indispensable asset for enhancing plant productivity.

Certifications, Delivery, and Payment for Agitator Systems

Our industrial agitator systems are certified to meet premier quality and operational standards, ensuring trust and reliability for every industry stakeholder. Experience quick dispatch and swift order completion, supported by clear payment terms and flexible exchange options. Delivery across India is prioritised for efficiency, giving customers peace of mind from purchase through installation. Choose us for a seamless buying process and authentic product certification.

Industrial Agitator System: Features & Applications

The industrial agitator system delivers high-performance mixing, automatic functionality, and lasting durability thanks to its polished mild steel construction. Engineered for both single and three-phase operation, it adapts seamlessly to the varied needs of industrial plants. Widely utilised across chemical, pharmaceutical, and food industries, its application area covers blending, homogenisation, and suspension tasksmaking it an indispensable asset for enhancing plant productivity.

Certifications, Delivery, and Payment for Agitator Systems

Our industrial agitator systems are certified to meet premier quality and operational standards, ensuring trust and reliability for every industry stakeholder. Experience quick dispatch and swift order completion, supported by clear payment terms and flexible exchange options. Delivery across India is prioritised for efficiency, giving customers peace of mind from purchase through installation. Choose us for a seamless buying process and authentic product certification.

FAQs of Industrial Agitator System:

Q: How is the industrial agitator system installed and used in plants?

A: The agitator system is installed by skilled technicians following standard procedures. Once connected to the appropriate power supply (220440 Volt and single/three phase), it operates automatically and is easily integrated into existing plant workflows for mixing, blending, or homogenising materials.Q: What are the main advantages of high-performance agitators for industrial plants?

A: High-performance agitators ensure uniform mixing, improve processing speed, and reduce downtime. Their automatic functions and polished mild steel construction provide reliable, long-lasting service in demanding industrial environments.Q: When can I expect delivery after placing an order for the agitator system?

A: We guarantee quick dispatch and order completion. Typically, delivery times vary depending on location within India, but most orders are fulfilled promptly to ensure minimal wait and immediate use in your facility.Q: Where can the agitator system be applied within industrial sectors?

A: The agitator system is utilised across various industries, including chemical, pharmaceutical, and food processing plants. Its robust design makes it perfect for tasks such as mixing, suspension, and homogenisation.Q: What certifications do your industrial agitator systems hold?

A: Our agitator systems are certified for quality and operational reliability, meeting industry standards required by Indian manufacturing and distribution sectors. Customers receive all necessary documentation upon purchase.Q: How does the payment and exchange process work for buyers?

A: Payments can be made through secure, clearly outlined terms and buyers benefit from exchange policies designed for convenience and satisfaction during order completion.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry